You have got to be kidding me! My own dream machine shop! What would I want in the dream machine shop? First, let’s start from the floor. It would be concrete of course with a light broomed finish for traction.

Non-slip is always good. The floor would slope to the middle of the room for good drainage. Each lathe would have a drainage trough so that any coolant or oil could drain away from the machines. After that, I think the building would have insulated walls and ceiling to keep out as much heat and cold.

A really good idea would be to have air conditioning in the building. Is that asking for too much? I don’t think so. Two rows of lathes with the middle being open for the aforementioned drainage. It would be a small shop but loaded with goodies.

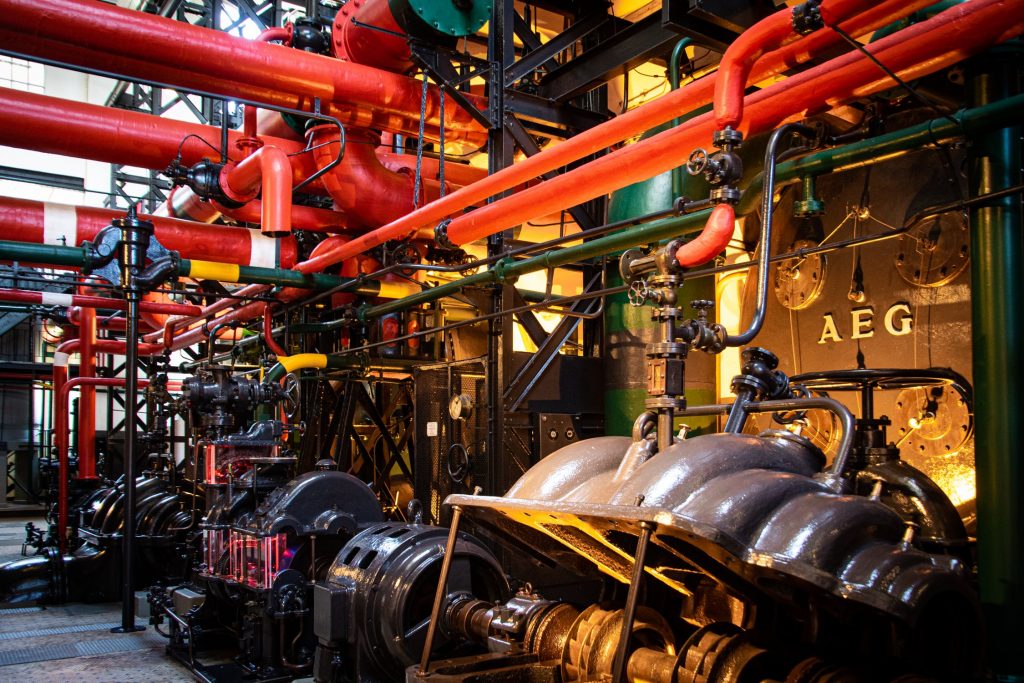

Each machine would be connected to the internet for a more comprehensive approach to the work. It will have the most innovative 3D machining that’s available from Revelation Machinery. The programmable interface will be the most user-friendly that the industry can produce. However, there is no beating good old fashioned man abled intelligence.

In this dream shop, I think the best thing that would be in there is a user-friendly environment. A workplace that is easy to work in. The workmen would have a stool in which they could get off their feet. This would allow them to change their position in order to reduce the muscle and bone stress on your back. This serves two purposes. One to increase production and two, more importantly, is to reduce injury.

Next, each workman would have a helper like in the old days. They would have an apprentice who would do the more menial tasks. The helper would assist the machinist with heavy lifting and performing some of the more simpler jobs.

Getting back to safety and health. The building would have a HEPA filtration system. This would filter out most of the more toxic fumes and air. This would reduce health risks that could cause cancer or other diseases later in the life of the workman. This might also be remedied by the worker using a filter mask although this may not be practical.

As far as noise pollution in the machine shop the traditional earplugs would be done away with. The actual lathe would be modified in such a way as to reduce the noise emanating from the machine by 50% if not more. The usual guards would be in place with the addition of an alarm system. This system would ideally alert the operator of any potential hazard.

The machine itself would have sensors that would almost predict a possible injury that could occur. All grinding in the shop would be handled by the helper with the aid of robots. Also, some of the monotonous tasks would be mostly performed by these robots. This would leave the machinist operator to be more like an administrator that would oversee the work.

These are just some of the things that I think would be great in a machine shop that would benefit both the individual worker and a company as a whole. There are many more innovations that I think would help production and workmanship but are too many to mention here. I am a firm believer in taking care of the employee’s needs and wants. this produces a happy and satisfied employee. This, in turn, boosts production levels.